Transforming Healthcare with Rapid, Cost-Effective Medical Device Manufacturing

— Robert Schiewe, Director of Orthotics

AUBURN, AL, UNITED STATES, December 2, 2024 /EINPresswire.com/ — XO Armor, a leader in additive manufacturing technology, has launched an innovative solution to streamline durable medical equipment (DME) production through advanced on-site 3D printing. XO Armor began as a method of providing immediate injury care in football, and has since been widely adopted by teams in multiple sports around the nation for custom on-site athlete protection. Leveraging their partnership with Bambu Lab, this pioneering approach for on-site capabilities aims to address critical healthcare challenges such as supply chain delays, high costs, and product shortages. These are addressed by empowering clinics to produce essential medical devices directly in-house.

Using Bambu Lab’s 3D printing technology, XO Armor enables healthcare providers to manufacture high-quality, customized medical devices at the point of care—without reliance on third-party suppliers or expensive external equipment. This rapid on-demand production model minimizes inventory expenses and reduces wait times for patients, enhancing both efficiency and patient outcomes. On-site production also significantly cuts costs, with prices less than half those of conventional DME, further democratizing access to critical healthcare resources.

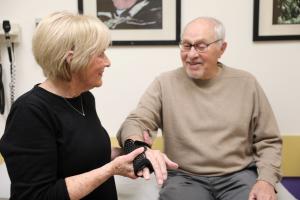

Additive manufacturing is especially impactful for creating custom-fit devices such as orthoses, splints, and other essential support equipment. Patients benefit from perfectly tailored devices that meet their specific needs and anatomical characteristics, while clinicians save time and resources by bypassing traditional casting methods. This shift allows medical professionals to dedicate more time to patient care, boosting overall treatment quality and satisfaction.

“XO Armor is delighted to partner with Bambu labs to transform healthcare delivery with a fast, flexible, and cost-efficient solution for medical device manufacturing,” said Joe Bingold, CEO of XO Armor. “Our platform not only streamlines clinic operations but also ensures patients receive high-quality, customized devices faster than ever.”

With breakthrough 3D printing technology, healthcare providers now have a powerful tool to elevate patient care and operational efficiency. For further information or to schedule a demonstration, please contact [email protected].

XO Armor

https://xoarmortech.com/

Sarah Cooley, Chief Marketing Officer

XO Armor Technologies

+1 971-241-6788

email us here

Visit us on social media:

X

LinkedIn

Instagram

YouTube

TikTok

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()